CFM® Materials

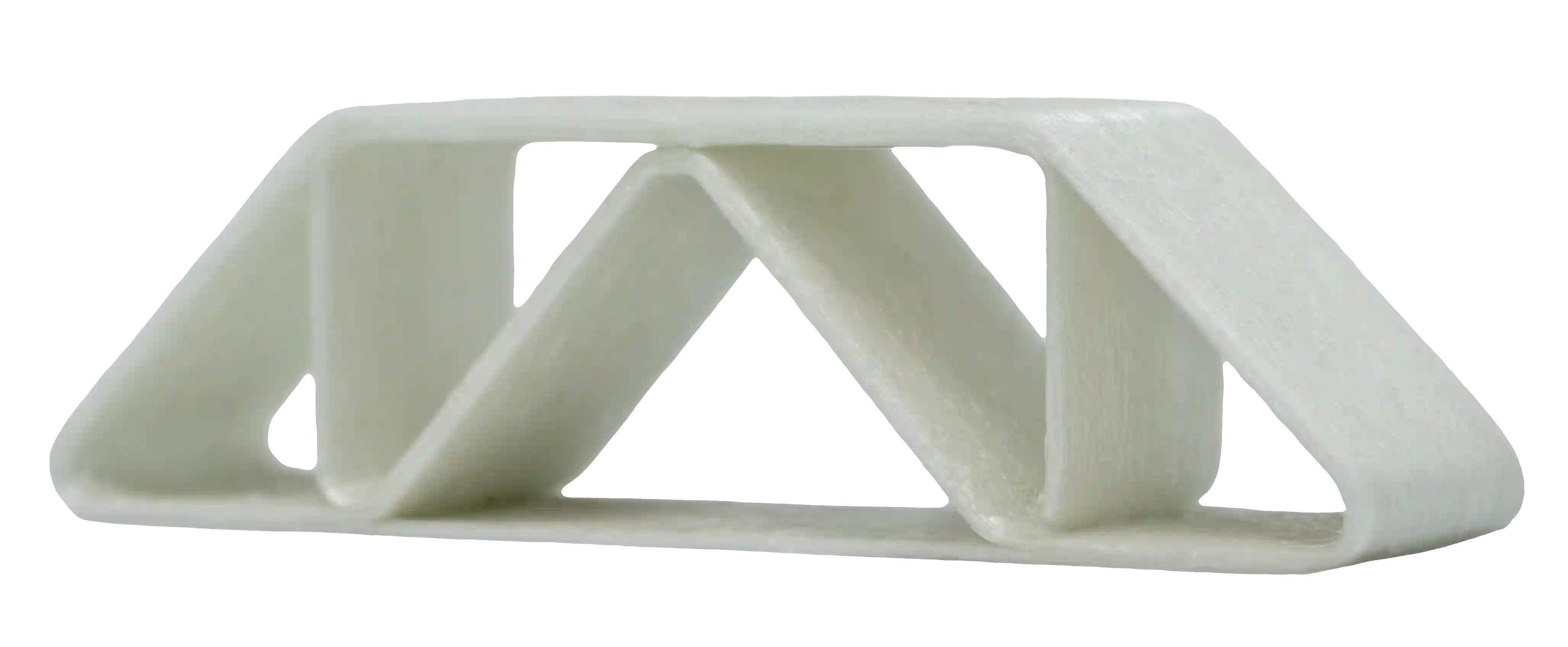

Next-gen thermoset composite AM materials featuring continuous fiber reinforcement.

A suite of thermoset matrix composites engineered for diverse application scenarios

Next-gen thermoset composite AM materials featuring continuous fiber reinforcement.

High-performance structural materials engineered for applications requiring high stiffness, strength, and lightweight efficiency

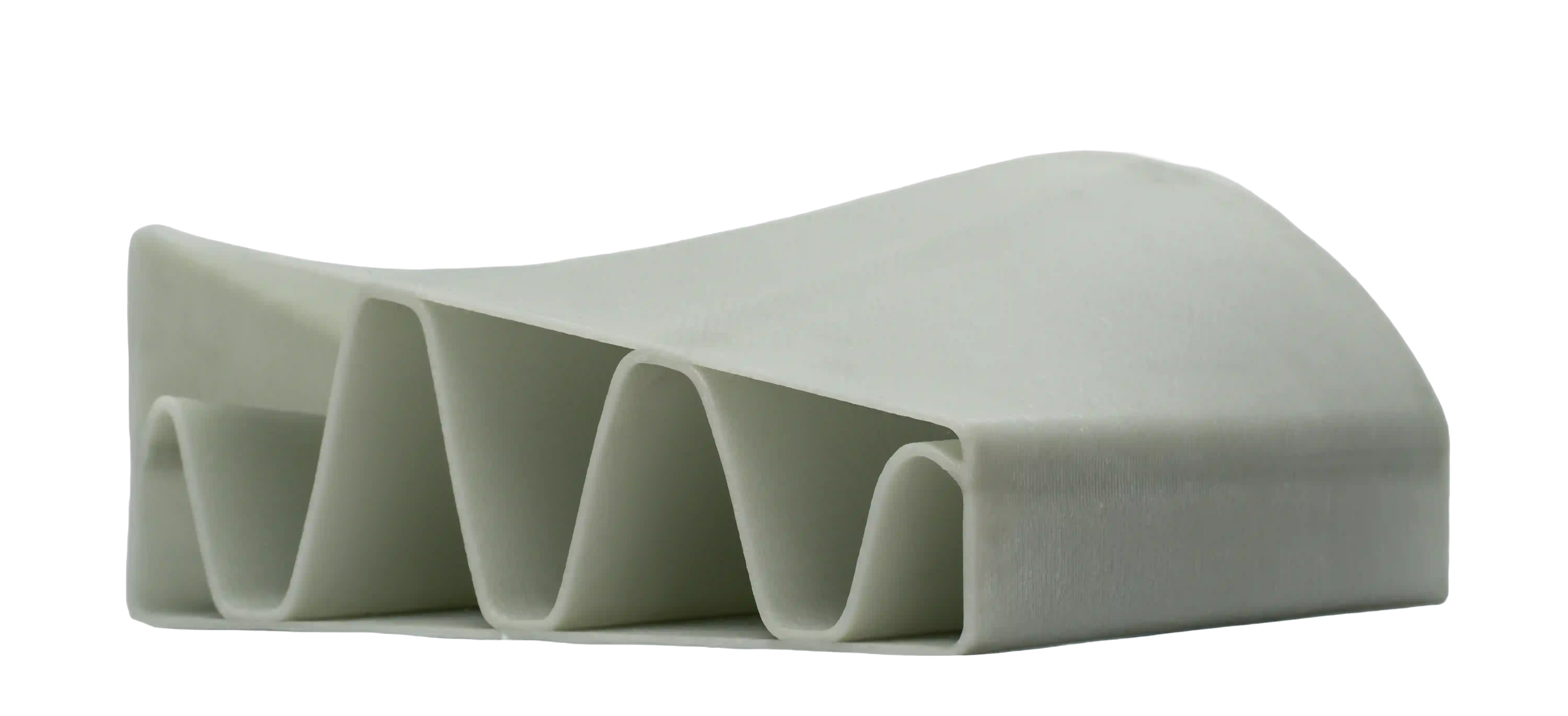

High-quality structural materials engineered to offer an optimal balance between structural performance, durability and cost-effectiveness

Highly filled thermoset composite AM materials featuring short fiber reinforcement.

High-quality structural materials engineered to offer an optimal balance between structural performance, durability and cost-effectiveness

Discover how our AM platform performs on your specific challenge